FIRE RESISTANT CABLES FOR MONITORING AND CONTROL CIRCUITS SPECIFICATION 3561-442-00217053-2012

- KUPPng(A)-FRHF,

- KUPplng(A)-FRHF

CABLES FOR MONITORING CIRCUITS, FLAME RETARDANT AT GROUP INSTALLATION NOT EMITTING COROSIVE ACTIVE GAS- EOUS PRODUCTS AT BURNING AND SMOULDERING (modification – “flame retardant – Fire-Resistant Halogen-Free”)

SCOPE AND PURPOSE

The cables are designed for transmission of signals with the operational voltage up to 250V of alternating voltage of frequency 50 Hz or of voltage up to 350V of direct voltage to 300mA in communication systems and fire protection systems for general industrial use, including buildings and structures of subway and for connection of transducers and actuators to software and hardware tools of APCS for laying inside the main process of the NPP, for operation outside the containment of nuclear power plants of class 2N, 2U, 3N, 3U and 4U according to classification NP-001.

The climate modification B, categories of location – 5, atmosphere type IV (coastal-industrial) according to GOST 15150.

Zerohalogen, non corrosive gases: GOST IEC 60754-2

Fire retardant: GOST IEC 60332-3-22

Smoky density: GOST IEC 61034-2

Fire resistant – 180 min: GOST IEC 60331-21

The class of fire hazard of the cables according to GOST 31565 – P1b1.1.2.1.

TECHNICAL DATA

| Increased ambient temperature, °C | limit | 70 |

| operating | 60 | |

| Düşük ortam sıcaklığı, °C | in a fixed installation | –40 |

| in conditions of installation bending radius are not less than 10 maximum outer diameters of cable | –15 | |

| High humidity up to 100% at temperature, °C | 35 | |

| Fungi score | not more than 2 | |

| Minimum service life of the cables, years | 40 | |

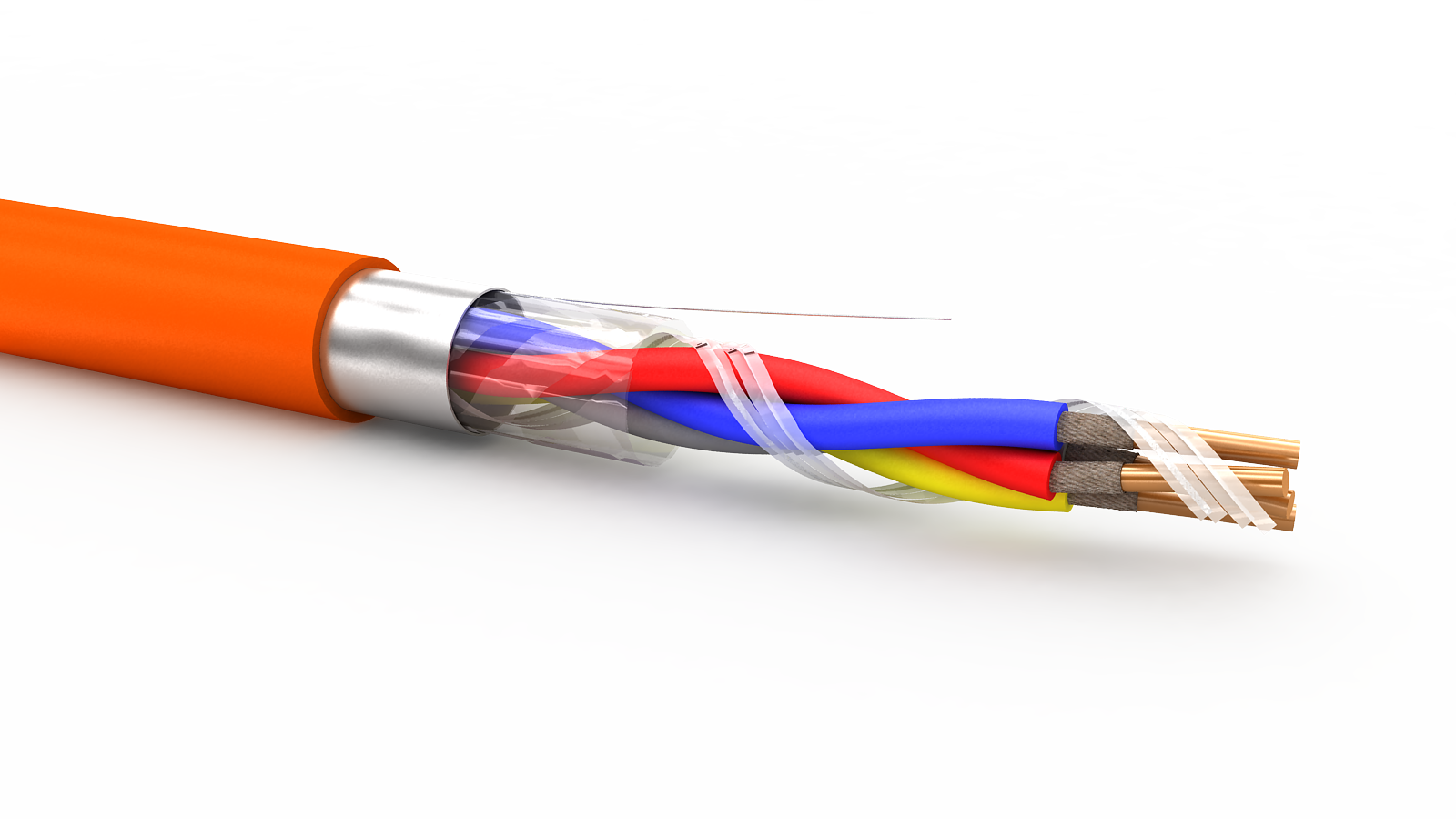

CONSTRUCTION

Number of pairs in the cable

1; 2; 4; 8; 12; 16; 20; 32 and 40.

Current-carrying conductor

Copper, or copper galvanized with the nominal diameter 0,8 mm (with cross-sections 0,5 mm2).

Thermal barrier

Taping with one mica tape.

Insulation

Halogen-free polymer composition. Color coded.

Core arrangement and twisting

Two insulated conductors with the general coloring of different colors are twisted in a pair. The pairs are twisted in basic four-pair bundles, the basic bundles are twisted in a cable core.

Belt insulation

Spiral overlapping with PET-E tapes.

Screen

Overlapping with alum polymer tape and a copper galvanized wire spiral longitudinally.

Over sheath

Halogen-free polymer composition of orange color.

The cables are resistant to salt mist

The cables are resistant to dynamic dust

The cables remain functional when subjected to earthquake intensity of 9 points on MSK