SMALL-SIZED CABLES, FIRE RESISTANT, FLAME RETARDANT AT GROUP INSTALLATION, WITH LOW SMOKE- AND GAS EMISSION SPECIFICATION 16.K71-337-2004

- KMPvVng(A)-FRLS,

- KMPvVEng(A)-FRLS,

- KMPvVEVng(A)-FRLS,

- KMPvEVng(A)-FRLS,

- KMPvEVEng(A)-FRLS,

- KMPvEVEVng(A)-FRLS

SMALL-SIZED CABLES FLAME RETARDANT AT GROUP INSTALLATION, WITH LOW SMOKE- AND GAS EMISSION (modification – “flame retardant – Fire-Resistant Low Smoke”)

SCOPE AND PURPOSE

The cables are designed for transmission and distribution of nominal electric energy and electric signals in stationary electric installations on nominal alternating voltage 0,5 and 1 kV and frequency up to 100 Hz or correspondingly on direct voltage 0,75 and 1,5 kV

The cables are manufactured for general industrial use and nuclear power stations.

The cables don’t spread combustion at group installation.

The cables are designed for use in cable structures and premises, including objects which use nuclear power, in the systems of NPP of class 2 according to classification of НП-001–2015.

The climate modification is Moderately Cold Climate, categories of location 1– 5, according to GOST 15150–69.

The class of fire hazard of the cables according to GOST 31565 – П1 б 1.2.2.2.

TECHNICAL DATA

| Nominal voltage, kV | 0,5; 1 |

| Ambient temperature during cable operation, °С | from - 50 to + 65 |

| The ambient temperature for laying and installation of the cables (without preheat) is made, °C, not below | -15 |

| Minimum bending radius, diameters of cable | 12 |

| Fire resistance of the cables, min, not less | 180 |

| Reduction of light permeability in the test chamber | not more than 50 % |

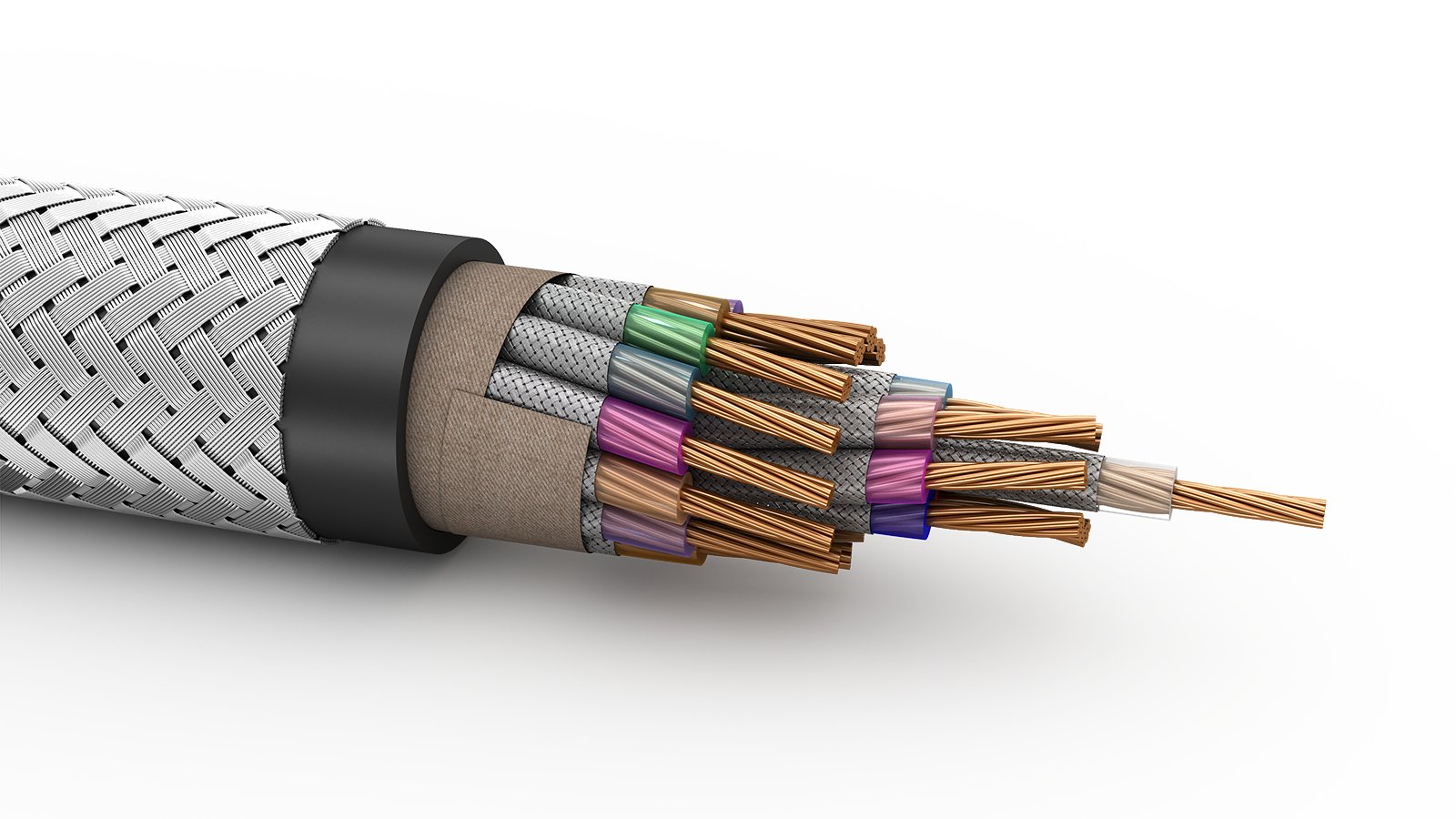

CONSTRUCTION

Current-carrying conductor

Copper, multi-wire of circular form, of the 3 or 4 class according to GOST 22483.

Thermal barrier

Taping with two mica tapes.

Insulation

XLPE (color or digital coded conductors).

Screen

For cables of types KMPvEVng(A)-FRLS, KMPvEVEng(A)-FRLS and KMPvEVEVng(A)- FRLS insulated conductors are screened or screened in pairs by braiding with copper galvanized or copper wires.

Core arrangement and twisting

Insulated conductors, screened cores and screened pairs are twisted in a cable core by concentric layer.

Taping

Of one fiber glass tape or mica tape

Inner sheath

PVC-compound of low fire hazard.

Overall screen

For cables of types KMPvVEng(A)-FRLS, KMPvEVEng(A)-FRLS and KMPvEVEVng(A)- FRLS is made in the form of braiding of copper, galvanized wires. For cables of types KMPvVEVng(A)-FRLS, KMPvEVEng(A)-FRLS and KMPvEVEVng(A)- FRLS a screen of copper wires is allowed.

Over sheath

PVC-compound of low fire hazard.