CABLES FOR CONTROL AND ALARM SYSTEMS, FLAME RETARDANT AT GROUP INSTALLATION, WITH INSULATION AND SHEATH OF HALOGEN FREE POLYMER COMPOSITIONS, FIRE RESISTANT SPECIFICATION 16.K71-338-2004

- KPEPng(A)-FRHF,

- KGPEPng(A)-FRHF,

- KUGPPng(A)-FRHF,

- KUGPPEng(A)-FRHF,

- KUGPPEPng(A)-FRHF,

- KUGPEPng(A)-FRHF,

- KUGEPPng(A)-FRHF,

- KUGEPPEng(A)-FRHF,

- KUGEPPEPng(A)-FRHF

CABLES FOR CONTROL AND ALARM SYSTEMS, FIRE RESISTANT, FLAME RETARDANT AT GROUP INSTALLATION AND NOT EMITTING COROSIVE ACTIVE GASEOUS PRODUCTS AT BURNING AND SMOULDERING (modification – “ngFRHF”)

SCOPE AND PURPOSE

The cables are designed for transmission of electric signals and distribution of electric energy in control circuits, alarm, communications, and unit connections of voltage 250, 380 and 1000 V of alternating current of frequency up to 200 kHz or at voltage correspondingly 350, 750 and 1500 V of direct current and keep working at fire.

The cables are manufactured for general industrial use and nuclear power stations (NPP) at usage out of under containment zone of NPP of classes 2, 3, 4 according to classification НП-001–2015.

The climate modification B, categories of location – 5, according to GOST 15150–69.

The fire resistance of the cables must be not less than 180 min.

The class of fire hazard of the cables according to GOST 31565– 2012 П1 б 1.1.2.1

TECHNICAL DATA

| Nominal voltage, kV | 250; 380; 1000 |

| Ambient temperature during cable operation, °С | from - 50 to + 50 |

| Minimum bending radius, diameters of cable | 6 |

| The ambient temperature for laying of the cables (without preheat), °C, not below | -15 |

| Fire resistance, min | not less than 180 |

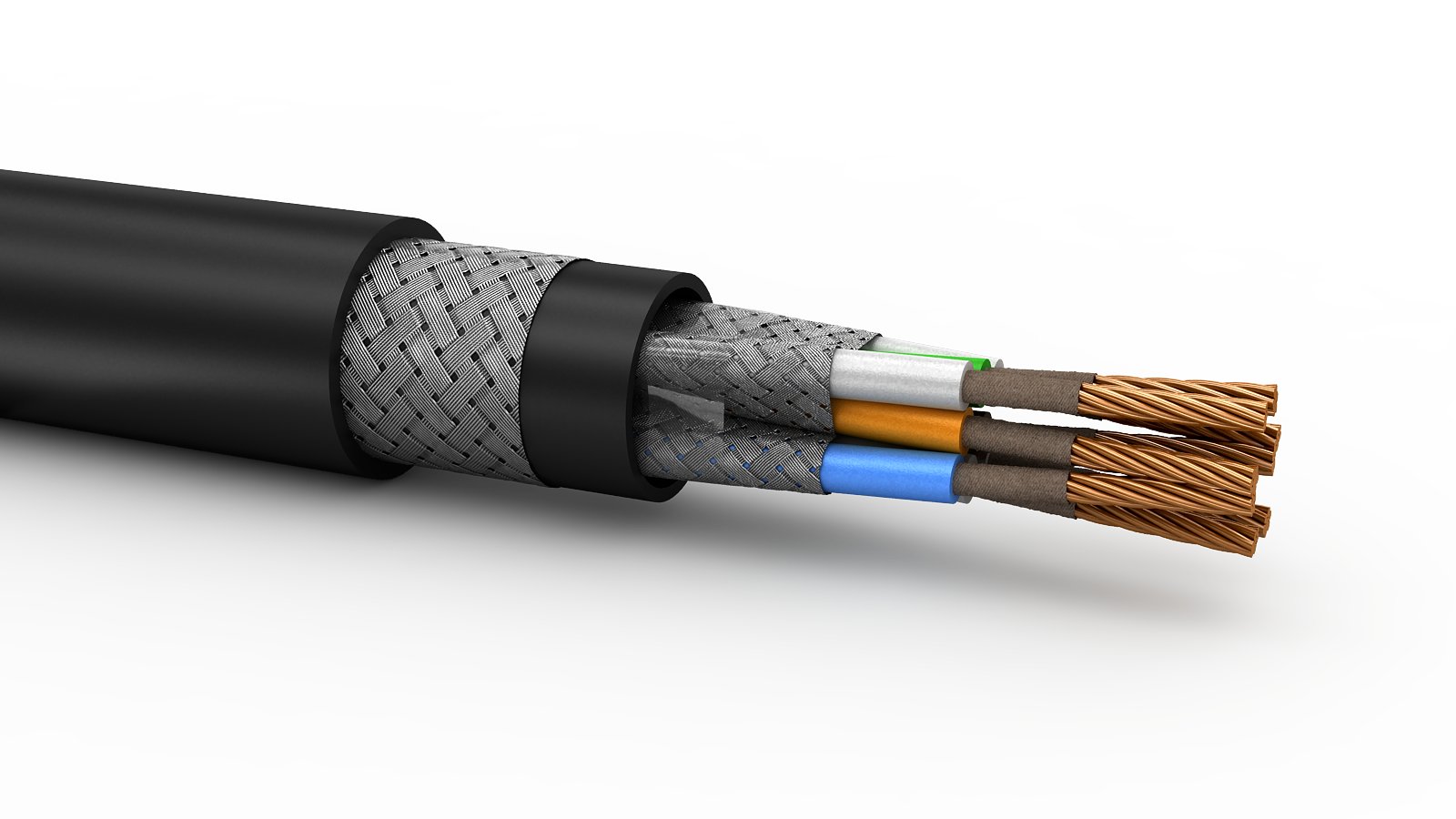

CONSTRUCTION

Current-carrying conductor

Copper, multi-wire or single-wire. For KPEPng(A)-FRHF – Russian equivalent of BiTflame AS(St) FE180/E90, JE-H (St)H… Lg FE180/PH90of the 1 class, for the rest ones of the 4 class according to GOST 22483–2012.

Thermal barrier for CCC (current-carrying conductor)

The lapping with two mica tapes.

Insulation

Halogen-free polymer composition.

Twisting in pairs

For cables with pair twisting the insulated conductors are twisted in pairs.

Screen over conductor

For KUGЕРРng(A)-FRHF, KUGЕРРЕng(A)-FRHF, KUGЕРРЕРng(A)-FRHF a screen of copper galvanized wire over the insulated conductor or a pair of insulated conductors.

Core arrangement and twisting

Insulated conductors, screened conductors, pairs and screened pairs are twisted in a cable core

Separating layer

For KUGPЕРng(A)-FRHF of halogen-free polymer composition. For the rest ones – taping with PET – E film

Inner sheath

For KUGPPЕРng(A)-FRHF and KUGЕРРЕРng(A)- FRHF – halogen-free polymer composition.

Screen

For KPEPng(A)-FRHF and KGPEPng(A)-FRHF)– a common screen in the form of foil, composite flexible material under the sheath, copper galvanized contact wire is laid under the screen. For KUGPPЕРng(A)-FRHF and KUGЕРРЕРng(A)- FRHF – a common screen in the form of braid of copper galvanized wire. For KUGPЕРng(A)-FRHF – a common screen in the form of braid of copper wire.

Over sheath

Halogen-free polymer composition.

Screen

For KUGPPЕng(A)-FRHF and KUGЕРРЕng(A)- FRHF – a common screen in the form of braid of copper galvanized wire over the sheath.